Hellens Manor, in Herefordshire, had some unique heating challenges, our biomass/solar solution met and exceeded them.

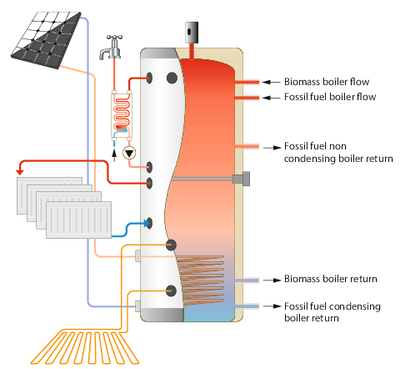

Every well designed biomass boiler installation needs a thermal store, sometimes called an accumulator. This is a large tank of water to store the heat generated by the boiler as hot water. It is connected to the biomass boiler water jacket and as the boiler runs, the heat from the fire box is transferred to the water jacket, heating the water. The hot water is pumped from the boiler to the thermal store. Cold water is in turn, drawn back from the bottom of the store into the boiler. The boiler is set to run until there is no more cold water left to heat, the whole tank is now full of hot water. This ensures that the boiler runs for enough time to get up to maximum efficiency, rather than start stop every time someone turns on a hot water tap or opens an exterior door lowering the temperature trip the thermostat, it is much better to do one long efficient burn, like a car getting up to working temperature and no longer needing the choke.

Every well designed biomass boiler installation needs a thermal store, sometimes called an accumulator. This is a large tank of water to store the heat generated by the boiler as hot water. It is connected to the biomass boiler water jacket and as the boiler runs, the heat from the fire box is transferred to the water jacket, heating the water. The hot water is pumped from the boiler to the thermal store. Cold water is in turn, drawn back from the bottom of the store into the boiler. The boiler is set to run until there is no more cold water left to heat, the whole tank is now full of hot water. This ensures that the boiler runs for enough time to get up to maximum efficiency, rather than start stop every time someone turns on a hot water tap or opens an exterior door lowering the temperature trip the thermostat, it is much better to do one long efficient burn, like a car getting up to working temperature and no longer needing the choke.

The water in the thermal store and the boiler is not the same water that comes out of the hot water taps for domestic use. That water is held within coiled pipes within the thermal store, these coils work like a heat exchanger, heating the domestic hot water as it is drawn through the coils on its way to the hot water tap.

If you are going to install a thermal store or accumulator, it is always worth considering getting one with the added facility of a solar panel input and the hot water produced from those panels can also be stored for use later.

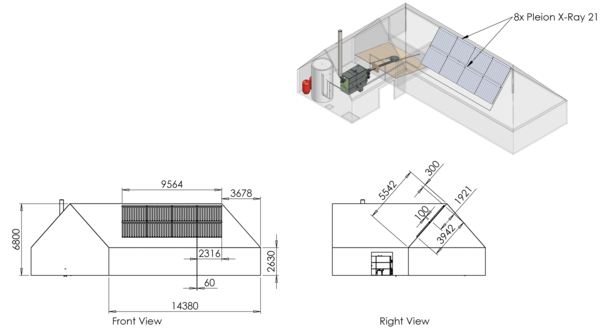

The solar thermal panels on the boiler room.

The buildings being heated.

On sunny days it may mean that the boiler is no longer required to run at all, on cooler days the solar heat input will increase the heat in the store to a level that reduces the amount of energy needed from burning wood to raise the temperature to required heat levels. This free source of hot water production, receives RHI payments as the heat generated goes through heat meters and is paid on heat generated.

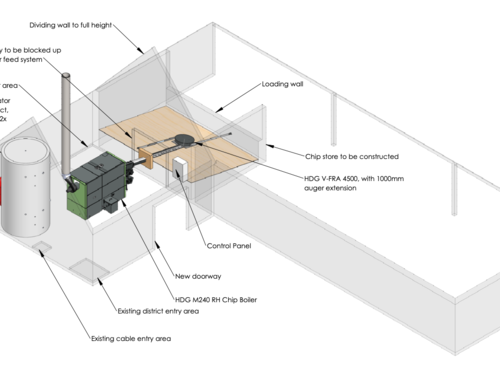

At Hellens, the large boiler room and chip store roof, which is south facing was an obvious choice for an array of eight X-Ray 21 1.955kWs panels, totalling 15.64 kWs, that feed the heat straight into the large accumulator in the boiler room.

Hellens has such a large heat demand across several separate buildings, that smaller, remote thermal stores have been added in each building, they are fed heat from the master thermal store in the boiler rooms when they require replenishment.

With this holistic view of the heating and hot water production, utilising different heat sources and balanced delivery to remote storage locations, Hellens is assured an efficient and reliable supply of heat and hot water in the future.

- On sunny days it may means that the boiler is no longer required to run at all, on cooler days the solar heat input will increase the heat in the store to a level that reduces the amount of energy needed from burning wood to raise the temperature to required heat levels.